Cool. The design is supposed to provide power to a BlueIris system for hours, possibly days. Key is avoiding AC-DC conversions to improve energy efficiency and hence maximize runtime. So what has to run and how do we run it?

As a starting step, I would take stock of what you have and what you actually need to run - first in terms of equipment, but also in terms of voltages to run same. In other words, what has to run vs. what can you live without? For example, for me there is no point trying to run high-speed TPC/IP communications with the outside world during widespread power outages as Comcast automatically shuts them down.

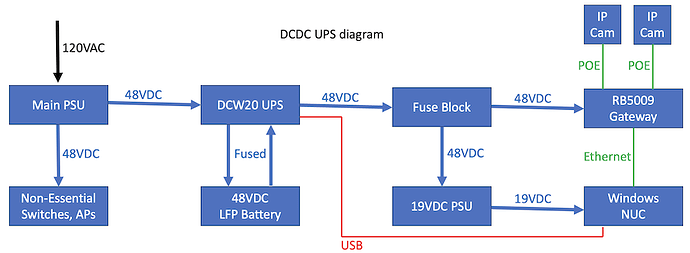

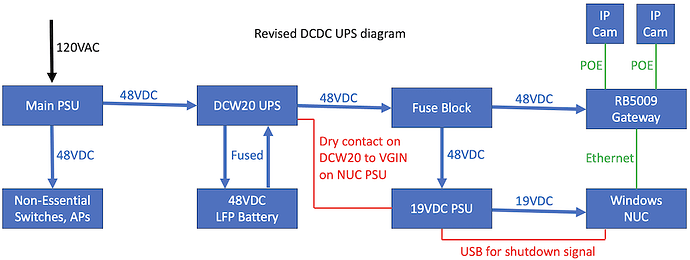

For surveillance equipment, the default POE voltage is 48VDC whereas the NUC that does the recording operates at 19VDC. Etc. So sketch out what has to run and figure out what kind of power you need - how many watts at what voltage. That in turn drives system design. For me, it’s 48VDC and 19VDC.

POE for cameras usually runs at 48VDC which I’m supplying from the gateway, a Mikrotik 5009 w/POE out. (I really like Mikrotik for the very wide input voltage ratings for most of its equipment). Meanwhile, my Intel NUC running BlueIris operates at 19VDC input.

Thus, my highest voltage had to be 48VDC. The DCW20 can step up voltages from 12 to about 50 VDC, but ideally, the DCW20 would act more as a pass-through. Thus, I chose 48VDC as a starting voltage.

I also needed power for the NUC and its associated cameras. For the NUC and a 12-27VDC switch I added a NUC DCDC power supply downstream from the DCW20 to supply the NUC and the switch with up to 6A at 19VDC.

Other, non-critical network hardware is also getting power from the PSU in this build (a Meanwell UHP-200-48) but most of the power it produces goes into a Nextys DCW20, which operates as a small, DIN-rail mounted DC-DC UPS.

What I love about the DCW20 is it’s simplicity, ease of connections, and compatibility with a wide range of battery chemistries. Allegedly, it’s PowerMaster UPS software will also cause my NUC to shut down when power gets low. That feature remains to be tested in anger.

Despite its Swiss origins, I found the DCW20 surprisingly simple to program. Four buttons do it all, though you can also access more in-depth features via a USB connection. There is also a built-in wizard that you can use. After running for hours while charging the battery, it has remained cool to the touch (it is charging only at 1A, however).

For the battery, I chose a 60Ah LiTime 51.2V battery with communications busses built in. I chose this battery on the basis of multiple reviews and the inclusion of ModBus and RS485, thinking it could communicate with the DCW20. This was likely a mistake, the RS485 / Modbus port on the battery is only apparently intended to connect to a display, while the DCW Mobus seems destined to talk to computers, not batteries. (The Modbus / RS485 connectors shipped with the LiTime battery appear like shrunken, and very proprietary versions of yesteryear DIN stereo connectors.)

Anyhow, as with any power buses at lower voltages, some attention has to be paid to the ampacity of the wires you’re using. Ideally, use fat pure-copper wiring, especially if moving lots of power at low voltages. Also, do not neglect to fuse your connections, no matter how fancy the BMS running the battery is supposed to be. 12AWG is the maximum the connectors for the DCW20 can comfortably manage. I like connectors with heat shrink built-in.

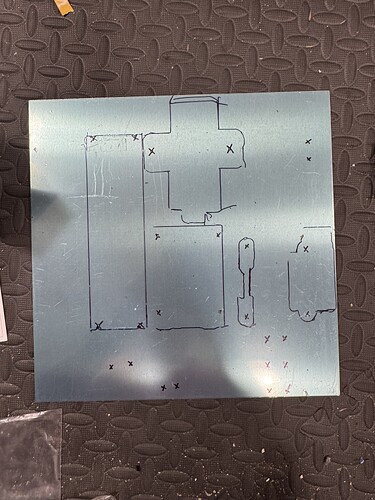

Then there is the issue of distributing the power, i.e. using power distribution blocks and common returns for DC power. I’ll hopefully get into that tomorrow when I’ll try to post some pics. Bottom line, it’s simpler than you think and it saves some money since the UPS market has yet to embrace providing UPS’ with multiple DC output voltages.