I recently had one of my older 48kHour He10’s start to throw SMART errors that included an inability to finish a short test, etc. Since I have gotten my money’s worth, I thought I’d extend my usual work life to home and have a look inside this disk. Specifically, I’m interested in how they build them differently from air-filled mechanisms.

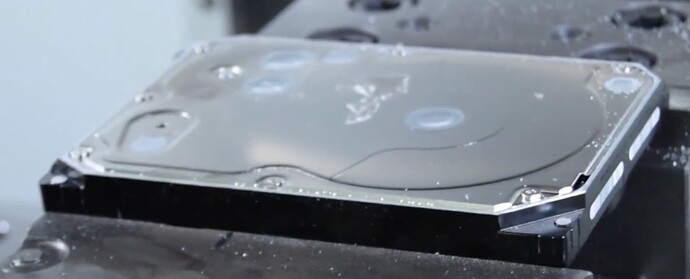

First, I peeled off the end protectors, which are basically thin strips of metal designed to protect the ends of the drives where insertion damage is most likely. Specifically, they protect the Al layer you see peeled below from nicks and like damage that would allow the Helium to escape.

The top layer itself seems to consist of a thick Aluminum tape-like layer that is tightly adhered to the underlying lid, covering all screws and sealing to the edges of the case itself. This is presumably the main seal. The actual metal lid fits inside the die-cast disk case, allowing the top edge of the case to be machined smooth and tightly-bonded with the Al-Tape around all the edges.

Using thick Al tape makes sense, He presumably diffuses very very slowly through the stuff, esp. at low pressure. Al is also used as a diffusion barrier in candy-wrappers - it’s what keeps your snickers bar fresh even after weeks in a vending machine - though in the case of the candy-wrapper the layer is only a few atoms thick and the molecule of interest is Oxygen, not the much-harder-to-contain Helium. Sputtering is your friend.

Inside, screw holes and like penetrations through the steel lid were covered with small sealing stickers as with most hard drives, save one. Presumably, that’s how the Helium was filled into the mechanism once they had evacuated the shell, followed by lidding with the thick Al Tape. I presume this is a batch process…

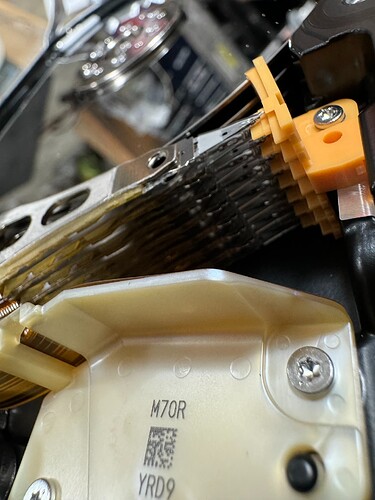

Once you unscrew the lid, the extra sealing around the edges becomes apparent, along with what I presume is some sort of filter / getter assembly glued to the underside of the lid. I presume all the Helium being inserted into the case is blown through this assembly. Or perhaps it’s simply there to absorb any moisture.

I have yet to take it off and take a closer look at it but the bottom reminds me of the Gore-Tex air filters that used to be pretty common on air-filled drives for pressure-equalization w/o allowing water to get in. It’s one of the better uses for Gore-Tex.

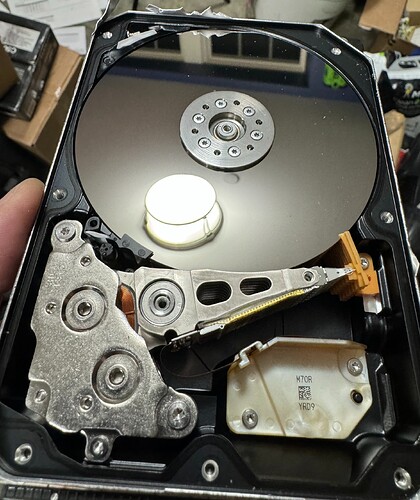

The platters / read/write heads are fairly similar to what I’ve seen in the past, save for the huge cutout in the bottom for the filter I mentioned above. Now that they have been extensively sprinkled in dust, I doubt they’ll be very useful.

The heads look pretty conventional and I was amazed just how many were in there.